High-Density Polyethylene (HDPE) liners serve as effective barriers against rainwater dilution in various containment applications, safeguarding stored liquids or materials from being compromised by excessive water intrusion. These liners, known for their impermeability and durability, play a pivotal role in maintaining the integrity and quality of contained substances.

Understanding Rainwater Dilution:

Rainwater intrusion poses a significant threat to stored materials, be it in landfills, ponds, or storage facilities. Dilution occurs when excessive rainwater infiltrates and mixes with stored liquids or substances, potentially compromising their composition and effectiveness.

Role of HDPE Liners:

HDPE liners act as reliable barriers, preventing rainwater from permeating through containment structures. Their impermeable nature serves as a protective shield, maintaining the concentration and quality of stored substances.

Impermeability and Durability:

The inherent properties of HDPE, including its impermeability and resistance to chemical and environmental degradation, make it an ideal choice for preventing rainwater dilution.

Applications in Containment:

HDPE liners find widespread use in various containment applications:

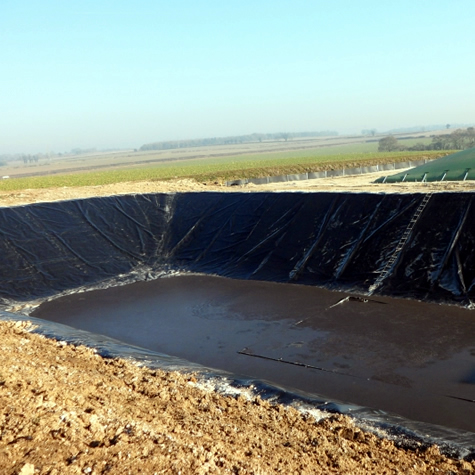

Landfills: They are used as primary barriers to prevent rainwater from infiltrating landfills and mixing with waste, thereby reducing leachate production.

Ponds and Reservoirs: HDPE liners ensure that rainwater does not dilute stored water in ponds or reservoirs, maintaining water quality and quantity.

Industrial Storage: These liners prevent rainwater from compromising the integrity of stored chemicals or materials in industrial storage facilities.

Installation Process:

Installing HDPE liners involves meticulous planning, site preparation, and precise installation techniques to create a continuous impermeable barrier. The liners are welded or seamed together to ensure a secure and watertight containment system.

Seaming and Welding Techniques:

Seaming and welding methods, such as heat sealing or fusion bonding, are employed to join individual sheets of HDPE liners, ensuring a seamless and durable barrier against rainwater intrusion.

Environmental Protection:

Preventing rainwater dilution with HDPE liners contributes to environmental protection:

Reduced Contamination: By maintaining the integrity of stored substances, HDPE liners help prevent environmental contamination caused by diluted materials.

Conservation of Resources: Protecting stored liquids or materials from dilution ensures their optimal use without wastage due to compromised quality.

Maintenance and Longevity:

Regular inspection and maintenance of HDPE liners, including checks for damage or deterioration, ensure their ongoing effectiveness and longevity in preventing rainwater dilution.

Cost-Effectiveness:

While the initial installation cost may vary, the long-term benefits of preventing rainwater dilution, such as preserving material integrity and reducing environmental impact, contribute to the cost-effectiveness of HDPE liners.

In conclusion, HDPE liners serve as robust defenses against rainwater intrusion, preserving the integrity and quality of stored substances in various containment applications. Their impermeability, durability, and contribution to environmental protection make them indispensable in safeguarding stored materials from the adverse effects of rainwater dilution.

To find out more about our products and services and how we can help you, please contact us using the below –

Tel: 01695 228626

Email: enquiries@enviroseal.co.uk