Containment Lining Systems

Enviroseal Containment Lining Systems

Waste Management

Anaerobic digestion is a waste management process that entails several phases in which biodegradable substances are broken down using micro organisms. This process can significantly reduce the amount of waste material that is typically generated, as well as producing useable materials that are resultant from the digestion process. Anaerobic digestion is a practical means to deal with waste products derived from industrial, commercial or domestic environments in a clean, efficient manner. The actual biochemical process is quite involved. Essentially, various chemical compounds and bacterial agents are utilized to breakdown and convert waste material into usable applications. When combined with other waste management processes, for example, anaerobic digestion can be effectively used to reduce the gasses that emanates from landfills and even reduce the amount of physical waste that these areas contain.

In addition to its waste management capabilities, anaerobic digestion can also create useable renewable energy as a result of the chemical interactions that it produces. This biogas can be used as fuel for cooking or even powering vehicles. Even the by-product ‘digestate’ of these systems can be used, producing a nutrient rich substance that works well as fertilizer.

Of course, anaerobic digestion systems can be configured in several different ways; from complex multi-digester tank affairs to systems that only utilize a single holding tank. The complexity of any particular system is generally dependent on specific function that it was designed to handle. Nevertheless, while the benefits of anaerobic digestion are fairly obvious and regardless of the actual size of the system itself, the confluence of chemicals that are involved in the digestion process can be environmentally hazardous at certain stages. As a result, tank integrity is a key component of the anaerobic systems.

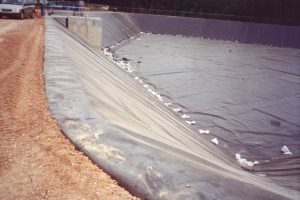

Containment Liners

Enviroseal is able to provide viable containment solutions for the prevention of leakage in anaerobic digester tanks (and for such by-products such as biogas that also must be stored). Digester tanks can be constructed with steel or concrete materials. Enviroseal can easily configure containment liners to accommodate whatever manner in which tanks are constructed. We carry a full assortment of liner options that are well suited for application in an anaerobic digestion environment. HDPE, LLDPE and polypropylene liners offer ideal chemical and gas resistance characteristics for projects of this type.

Indeed, because the number of anaerobic digestion systems has increased, Enviroseal has positioned itself to convey the benefits of its containment lining systems to this expanding area of waste management. Enviroseal is able to provide services directly related to the prevention of tank leakage and maintenance of tank integrity for both digester and biogas tanks. Enviroseal also offers refurbishment services for anaerobic digestion system tanks as well, which provides a significant cost-saving measure.

Biogas Reactor

Another interesting cost-saving application of geosynthetic liners is to use them as the means to construct a smaller version of a biogas reactor tank. Because anaerobic digestion is essentially a biochemical process, it is easy enough to reproduce and the resultant biogas is just as viable for use. This type of procedure is commonly limited to attaining biogas in small amounts, generally for personal use.

Biogas tanks of this nature, often referred to as rubber-balloon biogas reactors or plants are easy to build and very cost-effective. The basic idea is to have a containment area dug in the ground to hold the biochemical sludge (the primary waste ingredients commonly found in any home) that is necessary to produce the biogas. This containment area and sludge is then covered with a plastic sheet (or other impermeable cover such as a geomembrane containment liner) and allowed to gestate in the sun. The resulting gasses will form in the upper part of the plastic or containment lining cover, while the sludge settles to the bottom of the holding area. The gas can then be siphoned out as needed.

While this manner of anaerobic digestion is indeed viable, the implementation can be temporary and a bit haphazard. Its simple construction subjects rubber-balloon biogas tanks to the pitfalls of damage from the weather and normal wear and tear. Also, effectively collecting the biogas from the makeshift tank can be problematic at best. Nevertheless, Enviroseal’s geomembrane liners can innovatively be used to accomplish this task for those clients that embark on the endeavor.

It should also be noted that Enviroseal’s containment liners are fully compliant with regulatory guidelines that have been established by the Environment Agency, as well as HSE. Clients can be assured that our lining systems have been completely tested for quality and further certified by laboratories that are sanctioned by the UKAS for such accreditation. Enviroseal has worked on numerous anaerobic digestion system projects, giving us the practical experience, coupled with our technical expertise, to be the first choice solution for anaerobic digestion tank protection.