Water Irrigation Reservoirs

& Lagoons

Water Irrigation Reservoirs

& Lagoons

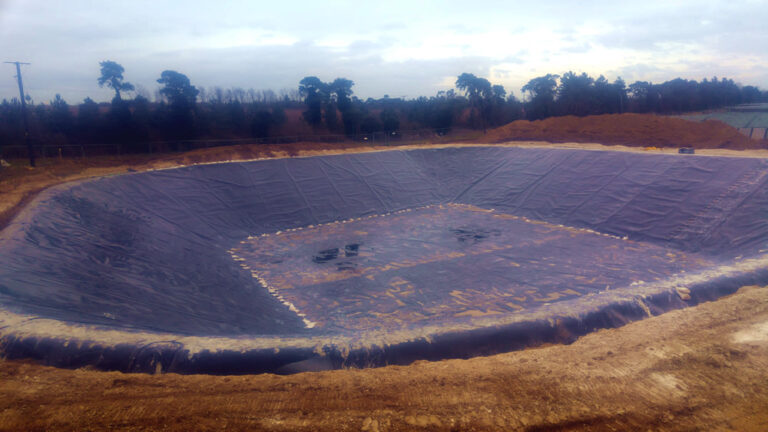

Reservoirs

The liner is welding using a double hot wedge welder. A heated wedge is pulled in intimate contact between two lapping liner surfaces, melting the molecules to the correct depth and temperature. Pinching rollers at the tip of the wedge compress the two molten surfaces onto each other allowing the molecules to bond before cooling down. A test channel between the two continuously welded tracks allows the weld seam to be pressurised (air pressure) to determine the integrity of the weld seam.

The materials are installed and tested to specification by our highly experienced technicians who are CSWIP certified by TWI. CSWIP is the nationally recognised qualification for geosynthetic installers and welders within the industry. TWI operates a Department of Trade and Industry accredited scheme for personnel certification in accordance with ISO/IEC 17024 through the United Kingdom Accreditation Service (UKAS).

Enviroseal provide a 25 year material and installation warranty on all projects.

Enviroseal are highly experienced in the installation and testing of HDPE and LLDPE liners and are:

- Members of the British Geomembrane Association

- Members of the International Association of Geosynthetic Installers

- Enviroseal’s management procedures are accredited to ISO9001 and provide fully traceable material documentation, installation reports and test records.

- All our site staff hold CSCS cards, first aid certificates as well as other task specific health and safety certificates. Supervisors hold Construction Site Supervisors Safety Certificates (SSSTS).

- Enviroseal are accredited to Safecontractor. Safecontractor is a leading third party accreditation scheme which recognises very high standards in health and safety management amongst UK contractors.